Description

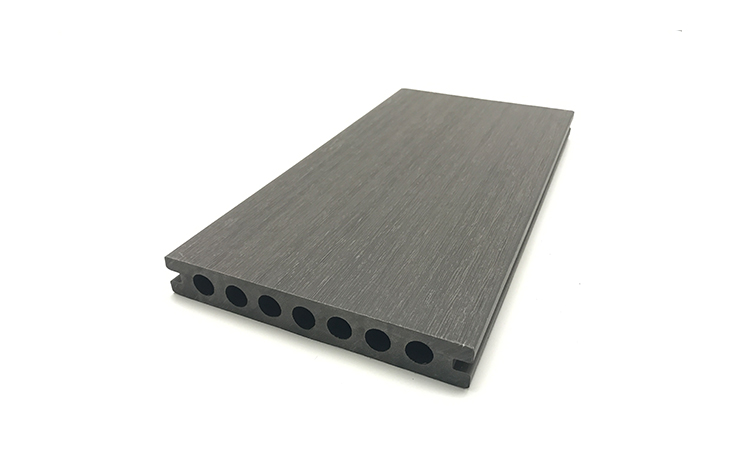

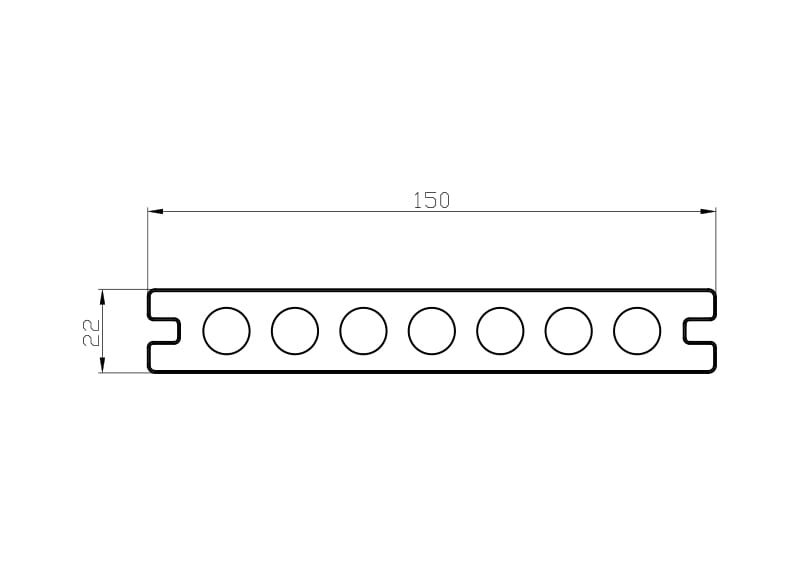

Our profile is 22mm thick, 150mm wide, and the product linear weight is 2.86kg/m. A hollow board of the same size will be about 1 / 3 lighter than a solid board. So it will be more convenient for transportation and installation. If you want to use light and strong materials, capped hollow composite decking is the ideal choice.

Generally speaking, the manufacturing process of capped hollow composite decking is more complicated. We use a round-hole hollow design, through a series of processes such as mixing, pelletizing, and coextrusion. In some extreme weather conditions, capped hollow composite decking has high stability and is not easy to expand or shrink.

Our 22mm x 150mm capped hollow composite decking is made of a mixture of recycled wood and high-density polyethylene (HDPE). The surface layer uses a 360- degree coverage design, including the top, bottom, and grooves to provide protection. Although the decking is hollow, due to scientific design and excellent manufacturing process, it still has strong anti-bending strength and is resistant to stains, color fading, wears and tear.

Our unique color mixing process can achieve the natural wood grain effect of the flooring, and each board has a more realistic appearance. In addition, we have 6 standard colors to choose from, complementing all architectural styles from modern to classic.

Colors

Surface Treatment

Accessories

-

- Solid and hollow substructures are optional, different size for different installation environment.

-

- Start rail can finish and seal your new decking, with the same material and formula as the decking boards.

-

- Secure the decking boards with the clips on the substructure and using the screws fix it.

-

- Start the installation, using the starting clip before fixing the first decking board.